I am in the middle of a network wiring closet makeover at work right now and thought that this would be the perfect time to go over some of the things that I have learned along the way. I feel like now that I have a few of these closet rewiring jobs under my belt I am confident enough in my techniques and methods to the point where I feel comfortable going over them and showing viewers how a wiring closet should be built out and should look when everything is said and done.

The only thing I will be covering in this post is the wiring portion of this process. The networking closets have been built out, the grounding racks and wires have all been rigged up and the wire management racks have all been installed. The switch chassis and PSU’s have all been mounted. The switch interfaces and other behind the scenes networking tasks have already been configured and taken care of. The point I’m trying to get at here is that there were a lot of hours spent taking care of all these small items and a ton of work done in the background to get to this point. I think the most important lesson to take away from this project was making sure all of the small things were done properly and with a certain expectation of quality, otherwise all of the other effort that went into one process will be wasted.

I am going to walk you through the process I went through to rewire a networking closet in the remainder of this post. Luckily I was able to take pictures for many of the things I went through along the way. I thought it would be useful to show rather than tell for the most part to make following things a little bit easier for readers.

Proper implements

Ethernet cables – Pretty obvious but I just wanted to mention this one quickly anyway. I have only seen a handful of bad cables but you can never be sure so having some extra cable to swap out is an easy way to test if a cable is bad or not. Also, we use a color coating scheme to help keep things organized, you will see later what I’m talking about. Just make sure you size out your cables to the appropriate length before hand.

- White cables – Wireless internet.

- Red cables – Generic printers.

- Green cables – Special purpose, whether it be static computers or specialized printers.

- Yellow – UPS

Velcro – Probably your most important tool and cannot be understated in my opinion. Effective use of velcro is really what ties everything together and keeps things organized and clean. Not sure how a set of cables should go? Velcro. It is your best friend if you have OCD and are working on one of these projects.

Label maker – Another great tool to help keep things organized. By no means do you need to label every cable in a wiring closet but you should be sure to highlight some of you landmark cables, so to speak. I’ve found it works out pretty slick to flag any static computer with a label, special printers, core uplinks, a basic rule of thumb I came up with is that any special case where you have a port you may easily forget later on should get labeled.

Wire cutters – Just about every closet I’ve had to reconfigure so far required me to use these for one thing or another. I like to have them handy just in case I need them.

Multitool/Razor – Handy for cutting the ends off of boots, lopping off pieces of velcro or just about any other odd job you might encounter in your wiring closet project. Another one of those nice to haves before hand so you don’t waste time later.

Music – It can get mighty boring doing this type of work. I suggest turning up some of your favorite tunes if you can, it will help you to keep your sanity. Listening to music may also work by keeping you distracted just a little bit as well as helping the time pass by.

The Buildout

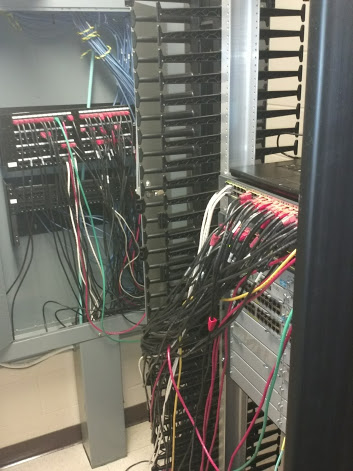

Here is what the wiring closet looked like initially. As you can see it was not exactly in great shape. Although this is not nearly as bad as what some closets look like that I have come across (including some others within the scope of this project even), but I still don’t like it. I came up with a game plan before hand, which turned out to be really useful.

Since there were only 2 VLAN’s in this closet, each on their own switch, and each VLAN correlated to one side of the patch panel, it made doing the cut that much easier. This method should be somewhat foolproof and could easily be applied in any situation as long as the ports on the switch and patch panel and their correlating VLAN’s are known ahead of time. Again, because this wiring closet was smaller than the others it made things less messy as well as less time consuming.

There isn’t much to this method really. The one caveat that really helped me in this closet is that we were not reusing the old patch cables. Not reusing the old cables allowed for two things. First, it made pulling out all of the old cable SO much easier and secondly, it enabled me to use some of the clipped ends as markers, so I knew where to plug all of the new cable runs into. I unplugged (or cut the ends) all the cables from one switch at a time, and traced the cable back to the port it was plugged into on the patch panel. Once I knew which port the cable was plugged into I would simply cut the end and leave it there, in place until I had traced the cable from end to end. By doing it this way I was able to keep the cables from each switch separate and using the boots gave me a quick and easy way to know where I was at. Here is an example of what I’m talking about.

My new switch was setup in a particular way. the first 4 slots on each card were designated as wireless ports (white cable), and the last 4 ports were designated to be printer ports and static ports (green, red, yellow). So that left me with the middle 16/12 ports for the cards, therefore the bulk of my bundles were sized to fill all the ports. With the few extra I just sized my bundle according to how many ports were left over. If that doesn’t make much sense, take a look below and you can kind of see what I’m talking about. I screwed up on the yellow cable there, it ended up being at the far right by the end of things.

There were a few things that I found to be useful when I was putting the new cables in. Probably the most important thing to be mindful of when patching in the new stuff is to count out your bundles correctly. I was dealing with some really long patch cable, so having to go back because I miscounted was a real pain in the ass. Here I am laying out my bundles because they are so *^#@ing lengthy, it would have been a nightmare trying to manage them without some sort of organization beforehand.

I found that it was much easier to handle these bundles if I had them all laid out and untangled ahead of time, just be sure to double count how many ports you need first! I will also say that it also helped me tremendously to have the ends tied up before running the bundles as well.

You can’t really appreciate the length of these cables are from these pictures but it was really painful and time consuming pulling some of these bastards. Again, having a game plan and rechecking things will be your best friend if you are rewiring a network closet. Here is how everything turned out when I was done buttoning up the closet and finishing up with some final touches.

Not bad. But I think just as importantly, at least for myself, all of the other parts of the closet need to look as good as the switch. I think the best way is to give you some other shots to show you what I mean.

It really isn’t that difficult to dress up a closet, and make everything look nice and neat. Time consuming? Maybe. But as you can tell from this rewiring job, this networking closet looks way better than it did before, I actually found a sense of pride and enjoyment from the work done on dressing up these wiring closets. It may not be a lot, but I am strong believer in the small things counting. Let me know if you have any questions or would have done any of this differently. I am always experimenting with my wiring technique and would love to improve on this method if I can.